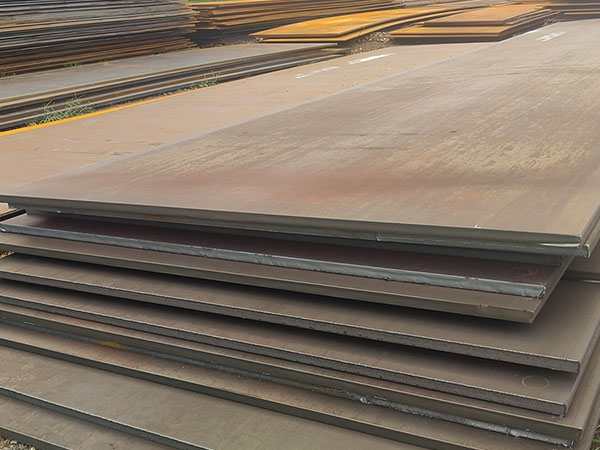

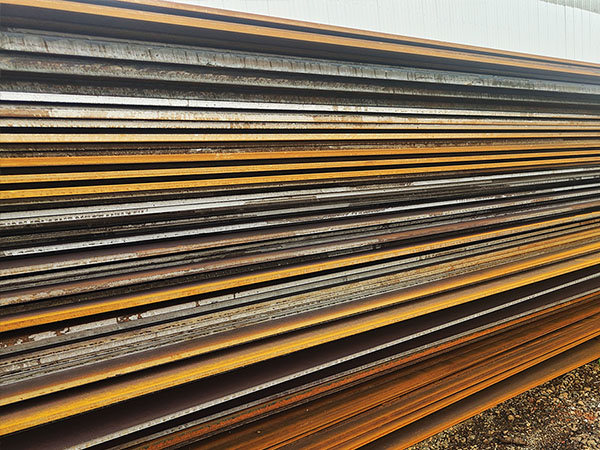

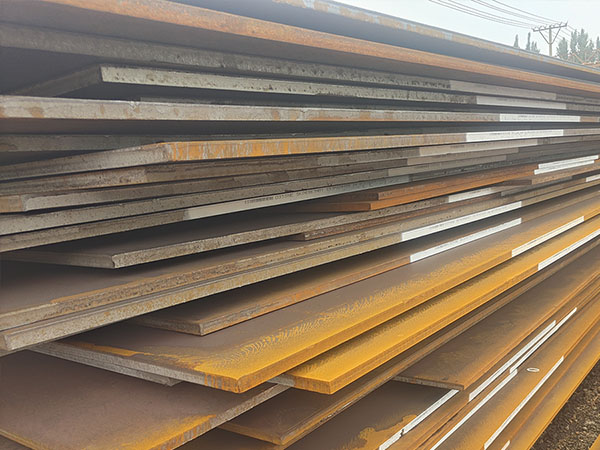

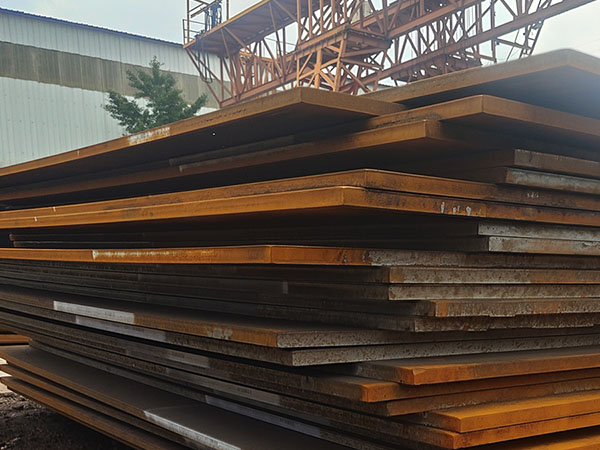

S500Q High Strength Steel Plate

S500Q High Strength Steel Plate

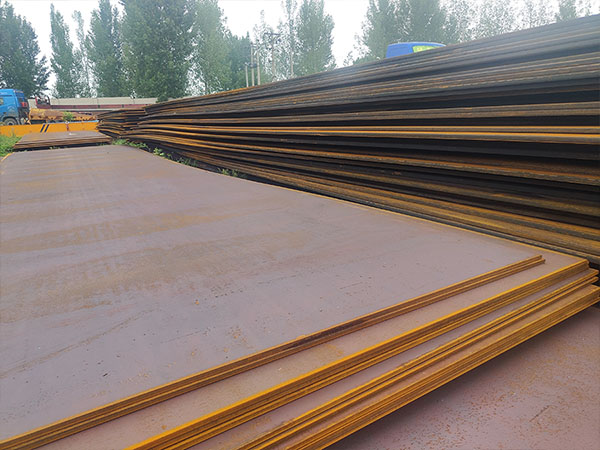

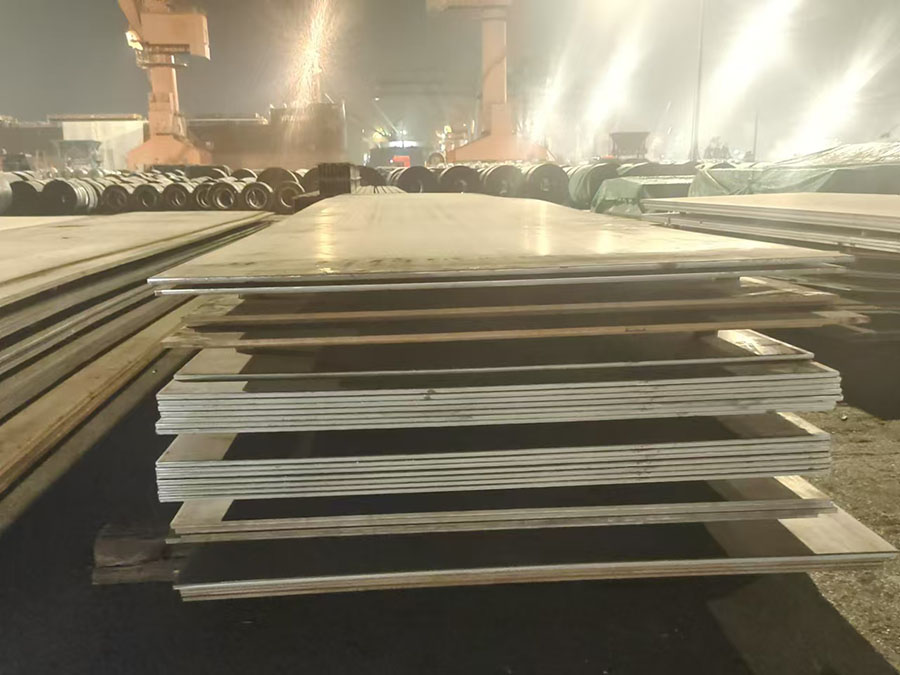

EN 10025-6 S500Q is a thermomechanically rolled, quenched and tempered fine-grained structural steel plate with a minimum yield strength of 500 MPa.

Standard :

EN 10025-6Grade :

S500Q-

Thickness :

3 - 100 mm -

Width :

1500 - 2500 mm -

Length :

3000 - 12000 mm

Special thickness, width, and length can be negotiated separately.

We also provide customized processing services.If you have any questions, please contact us.

Customer Cooperation

Customers choose to engage in long-term cooperation with Yuxin Steel not only because of our high-quality products and services, as well as our strong reputation in the international market, but also due to our experienced one-stop raw material supply and further steel processing capabilities!

Do you also have steel processing (machining) needs?

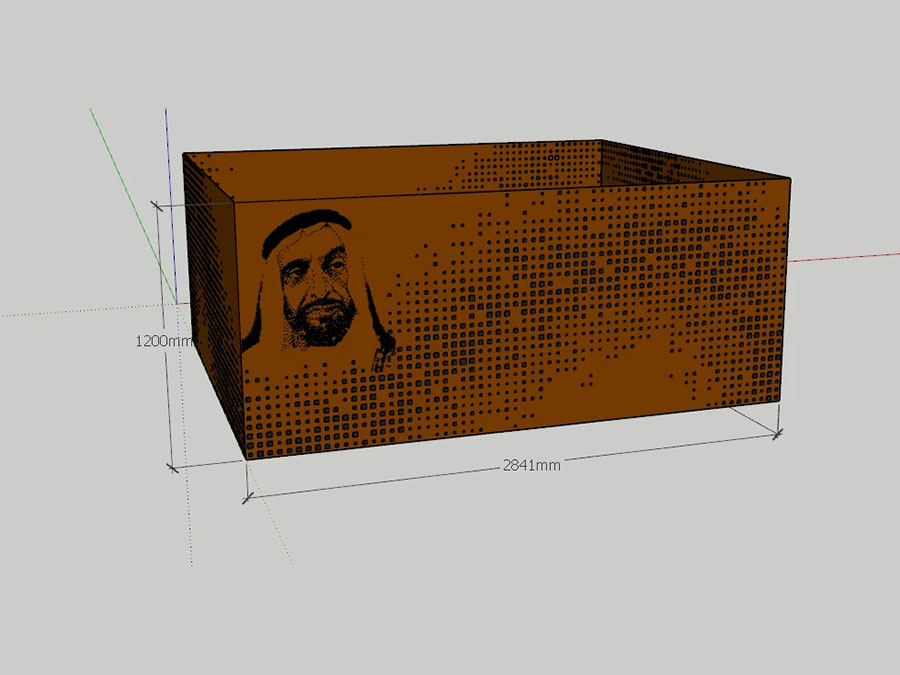

Yuxin Steel provides customized steel processing services based on drawings, samples, designs, and various special requirements, offering one-stop solutions for steel procurement and processing needs.Contact Info

Get In Touch

Would you like to know more about our offers? Please feel free to contact us.