Yuxin Steel will participate in the 19th Build Asia Internat...

- Dec 19, 2025

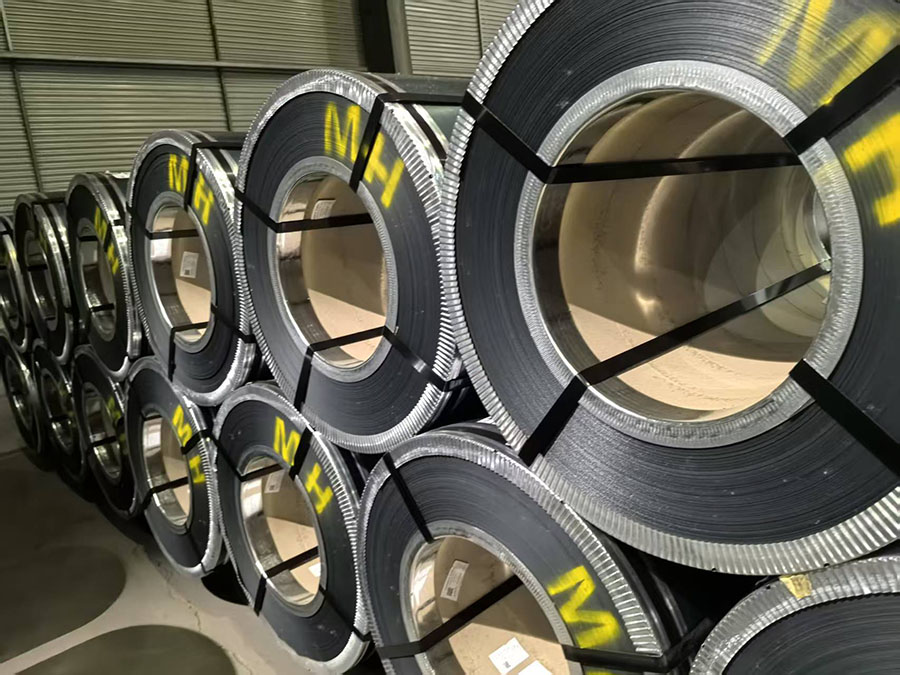

A successful cooperation case between our company and a major Pakistani manufacturer of steel pipes and structural steel. The customer sought high-quality and cost-effective steel raw materials to enhance its market competitiveness. The SPHT1 heat-treated steel coil provided by our company perfectly met its requirements, establishing a stable supply chain partnership.

Pakistan is currently in a phase of rapid development in infrastructure construction, real estate, and the energy sector, leading to sustained strong demand for high-quality steel. Local manufacturers, particularly those producing steel pipes (for water pipes, gas pipes, structural pipes), stamping parts, and profile manufacturers, require large quantities of stable-performance, high-surface-quality cold-forming substrates.

In this context, our company engaged with a leading "Steel Pipe Manufacturing Company" in Pakistan. Renowned for producing high-standard welded steel pipes and complex cold-formed profiles, the company faced challenges with its original suppliers in terms of material consistency, delivery cycles, and cost control. They urgently needed to find a reliable and competitive overseas steel supplier to ensure production continuity and maintain product quality leadership.

Through in-depth communication and technical exchanges, we identified the company’s specific needs:

Grade and Standard:

Explicit requirement for heat-treated steel coil conforming to the SPHT1 standard (Japanese standard JIS G3131). This material must possess excellent formability, weldability, and moderate strength, making it an ideal choice for manufacturing complex structural components and pipelines.

Stable Mechanical Properties:

Yield strength, tensile strength, and elongation must consistently fall within the standard range to prevent cracking or wrinkling during stamping and rolling processes.

Superior Surface Quality:

The "heat-treated" process requires minimal scale, uniform color, and no severe corrosion to reduce the cost and time for subsequent pickling or polishing by the customer.

Seeking a supply solution with cost advantages over high-priced materials from Europe, Japan, and local sources, while ensuring quality, to enhance the price competitiveness of their end products.

On-Time Delivery:

Strict adherence to production and shipping schedules to prevent production line downtime due to material shortages.

Logistics Assurance:

Safe and timely sea freight from Chinese ports to Karachi Port, Pakistan, with clear logistics tracking.

Secure Packaging:

Use of rust-proof, moisture-resistant, and robust packaging to withstand long-distance sea transport and potential rough handling at local ports.

4) Comprehensive Technical and After-Sales Support:

The supplier must provide detailed technical documentation (MTC) and promptly respond to technical inquiries regarding material usage.

To address the company’s needs, we developed and implemented a comprehensive solution:

Provided heat-treated coil fully compliant with the JIS G3131 SPHT1 standard, strictly controlling chemical composition (e.g., C, Mn) and ensuring mechanical properties exceeded the standard’s lower limits.

Utilized advanced heat treatment processes to ensure thin and uniform iron oxide scale on the coil surface, presenting a uniform blue-black appearance, significantly reducing pre-processing steps for the customer.

Each batch of products was accompanied by internationally recognized third-party inspection reports (e.g., SGS/BV) and detailed mill test certificates.

Leveraged the scale and production efficiency advantages of China’s steel industry to offer more favorable prices than materials from Japan and South Korea.

Provided flexible trade terms (e.g., CFR Karachi) and assisted the customer with import clearance documentation, reducing overall procurement complexity.

Production Prioritization: Designated the company as a key account, prioritizing production scheduling and securing delivery timelines.

Professional Logistics: Established long-term cooperation agreements with top-tier shipping companies to secure space and utilized specialized coil steel containers to ensure cargo safety.

Robust Packaging: Used high-strength steel strapping, lined with anti-rust paper/VCI (Vapor Corrosion Inhibitor) film and wrapped with waterproof woven cloth for comprehensive protection.

Dispatched technical sales engineers for online technical exchanges to confirm all technical details.

Established a dedicated customer service group, providing responses to order, logistics, and technical inquiries within 24 hours.

Proactively followed up on material usage and collected feedback after the first shipment arrived.

The results of the cooperation were reflected in the following:

Customer feedback indicated excellent material formability, with the product yield rate increasing by approximately 5%, and the appearance quality of the products receiving positive reviews from their downstream customers.

Overall procurement costs decreased by approximately 8–12% compared to their original channels, significantly enhancing the market competitiveness of the company’s products.

Achieved a 100% on-time delivery rate, ensuring the smooth operation of the customer’s production plans and greatly strengthening mutual trust.

Based on the success of the first order, the company has listed us as a core supplier and initiated discussions on long-term procurement framework agreements for other steel specifications (e.g., SPHC, SS400).

This cooperation was not merely a successful product export but also a successful example of our company’s in-depth understanding of the Pakistani market and our customer-centric approach to providing customized solutions. It has established a strong reputation for us in Pakistan and across the South Asian market, laying a solid foundation for future business expansion.