Yuxin Steel will participate in the 19th Build Asia Internat...

- Dec 19, 2025

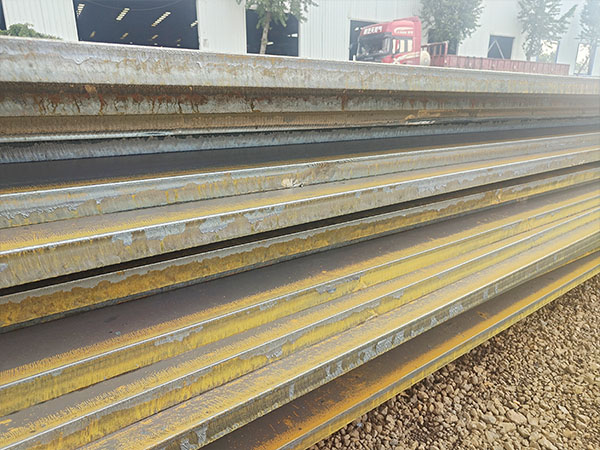

S420M is a high-strength low-alloy structural steel (compliant with EN10025-4 standard). During welding, it is essential to balance its strength, toughness, and weldability to avoid issues such as cracking and degradation of properties. The following are key considerations for the welding process:

1. Selection of Welding Method

Prefer low-hydrogen welding processes, such as Shielded Metal Arc Welding (SMAW), Submerged Arc Welding (SAW), Gas Metal Arc Welding (GMAW/MIG), or Flux-Cored Arc Welding (FCAW), to reduce hydrogen content in the weld and minimize the risk of cold cracking.

Avoid using high-hydrogen electrodes (e.g., acidic electrodes like E4303), unless weld performance requirements are extremely low.

2. Matching of Welding Materials

The strength of the welding materials should match that of the base metal (typically using electrodes/fillers with a yield strength ≥420 MPa), such as:

Electrodes: Low-hydrogen electrodes E5015-G, E5515-G (equivalent to E42 5 G, E50 5 G per EN standards);

Wire: ER50-G, ER55-G (equivalent to G4Si1, G5Si1 per EN standards), used with argon-rich shielding gas (e.g., 80% Ar + 20% CO₂).

Welding materials must be thoroughly dried (low-hydrogen electrodes dried at 350–400°C for 1–2 hours) and stored in a holding oven at 80–100°C, to be used immediately to prevent moisture absorption.

3. Preheat and Interpass Temperature Control

Preheat temperature: Adjust based on plate thickness and restraint conditions. General recommendations:

Plate thickness <25 mm: Preheat to 80–120°C;

Plate thickness 25–50 mm: Preheat to 120–150°C;

Plate thickness >50 mm or highly restrained structures: Preheat to 150–200°C.

Interpass temperature: Maintain not lower than the preheat temperature and not exceeding 300°C (to prevent grain coarsening and loss of toughness).

Use an infrared thermometer to monitor temperature, ensuring uniform heating (avoid localized overheating or insufficient temperature).

4. Control of Welding Parameters

Use low heat input welding: Control current, voltage, and travel speed to avoid excessive heat input (recommended heat input ≤25 kJ/cm), preventing grain coarsening and reduced toughness in the heat-affected zone (HAZ).

In multi-pass welding, the thickness of each layer should not exceed 1.5 times the electrode diameter. Remove slag and spatter between passes to avoid slag inclusions.

Fill craters at the end of the weld to prevent crater cracks (using techniques such as backstepping or current decay devices).

5. Post-Weld Treatment

Hydrogen removal treatment: For critical structures, perform immediate post-weld heating at 250–350°C for 1–2 hours to accelerate hydrogen diffusion and reduce the risk of cold cracking.

Stress relief annealing: For highly restrained structures or those subjected to dynamic loads, perform stress relief at 550–620°C (soaking time calculated based on plate thickness, typically 2–4 hours). Avoid excessive temperatures to prevent loss of base metal strength.

Cooling rate after welding: Avoid rapid cooling (e.g., take wind protection and insulation measures when welding in windy or low-temperature environments). Slow cooling facilitates hydrogen escape.

6. Welding Environmental Requirements

When the ambient temperature is below 0°C, preheat to at least 80°C or suspend welding.

When humidity exceeds 85%, remove moisture from the workpiece surface (e.g., by heating and drying) and enhance moisture protection for welding materials.

Protect the welding area from wind and rain to avoid disruption of shielding gas effectiveness (especially for gas-shielded welding).

7. Groove Design and Preparation

Select groove type based on plate thickness (e.g., V-groove, X-groove) to ensure penetration and minimize filler material. Groove angle is typically 60°–70°.

Thoroughly clean the groove and adjacent areas (within 20 mm) of oil, rust, scale, etc., before welding, using mechanical grinding or chemical cleaning (e.g., wire brushing, sanding, or pickling) to prevent porosity and inclusions.

8. Quality Inspection

Visual inspection: The weld surface must be free of cracks, porosity, undercut (depth ≤0.5 mm), lack of fusion, and other defects.

Non-destructive testing: Critical structures require Ultrasonic Testing (UT) or Magnetic Particle Testing (MT) to detect internal and surface cracks.

Mechanical testing: When necessary, perform tensile and impact tests on the weld (especially low-temperature impact testing to ensure impact energy ≥34 J at -20°C).

Adhering to the above considerations will effectively ensure the strength, toughness, and integrity of S420M welded joints, meeting structural and service environment requirements. For actual welding, develop a detailed Welding Procedure Specification (WPS) and qualify the procedure based on the specific structure, plate thickness, and working conditions.

View the chemical composition of EN 10025-4 S420M high strength low alloy steel plate >>