GB713 13MnNiMoR Boiler And Pressure Vessel Steel Plate

GB713 13MnNiMoR Boiler And Pressure Vessel Steel Plate

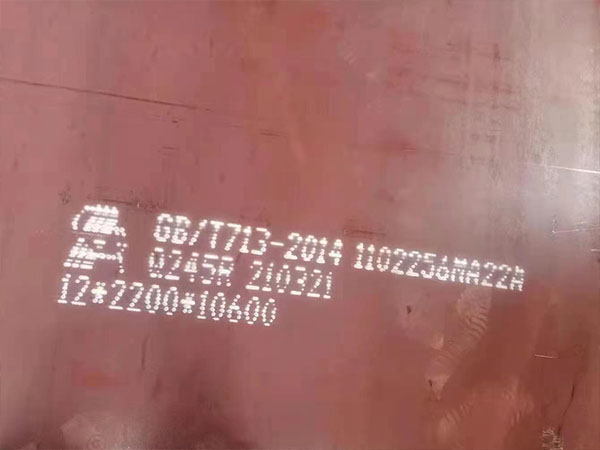

13MnNiMoR is a kind of low-alloy high-strength steel plate for boilers and pressure vessels, specified in the Chinese national standard GB/T 713 (current latest version: GB/T 713-2014 Steel Plates for Boilers and Pressure Vessels).

Standard :

GB/T 713Grade :

13MnNiMoR-

Thickness :

6.0-300.0 mm -

Width :

1500-4050 mm -

Length :

3000-15000 mm

Special thickness, width, and length require negotiation.

We also provide customized processing services.If you have any questions, please contact us.

General Description of 13MnNiMoR

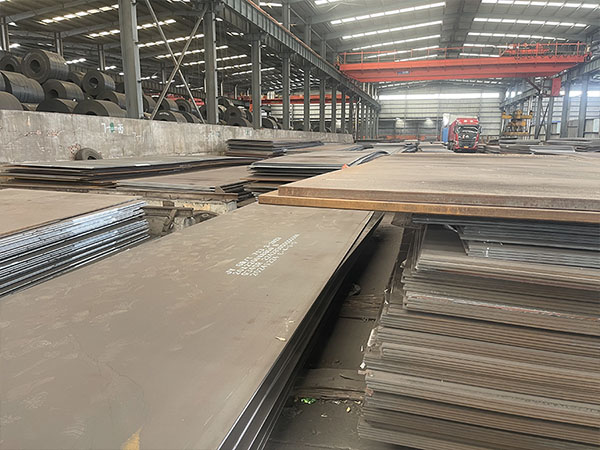

GB713 13MnNiMoR is a kind of low-alloy high-strength steel plate for boilers and pressure vessels, specified in the Chinese national standard GB/T 713 (current latest version: GB/T 713-2014 Steel Plates for Boilers and Pressure Vessels). It is widely used in the manufacturing of critical pressure-bearing equipment due to its excellent comprehensive performance.

The characteristics of 13MnNiMoR pressure vessel steel plate are as follows:

1. Excellent low-temperature impact toughness and weldability

2. Good machinability and formability

3. High heat resistance and oxidation resistance

4. Strong pressure resistance and high strength

5. Suitable for low-temperature environments below -70°C

In summary,GB713 13MnNiMoR is a key material for high-reliability pressure-bearing equipment, with its performance strictly regulated by GB/T 713 to ensure safety in critical industrial applications.

Chemical Composition of 13MnNiMoR

| Grade | GB713 13MnNiMoR | ||||||||

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | Nb |

| Content(%) | ≤0.15 | 0.15-0.50 | 1.20-1.60 | ≤0.020 | ≤0.010 | 0.20-0.40 | 0.60-1.00 | 0.20-0.40 | 0.005-0.020 |

Mechanical Properties of 13MnNiMoR

| Grade | Yield Strength | Tensile Strength | Elongation | Impact Toughness (KV) |

| GB713 13MnNiMoR | ≥390 MPa | 570-720 MPa | ≥18% | ≥ 34 J at 0°C |

Applications of 13MnNiMoR

Due to its excellent pressure resistance, toughness, and weldability, 13MnNiMoR is mainly used in the manufacture of large pressure-bearing equipment, such as:

1. Hydrogenation reactors and coking towers in the petrochemical industry

2. Gasifiers and high-pressure heat exchangers in the coal chemical industry

3. Pressure vessels in the power industry, etc.

4. It is suitable for working conditions withstanding medium and high pressure, medium and high temperature (≤400℃), and where corrosive media such as hydrogen sulfide may exist.

Other Information

Heat Treatment

The standard requires 13MnNiMoR to be delivered after normalizing + tempering (N+T). This process refines the grain structure, reduces internal stress, and balances strength and toughness, ensuring stable performance under long-term pressure and temperature loads.

Welding Performance

13MnNiMoR has good weldability but requires proper welding procedures due to its alloy content:

Preheating is usually needed (preheating temperature: 150 - 250℃) to prevent cold cracking.

Post-weld heat treatment (PWHT) is recommended (tempering at 600 - 650℃) to reduce welding residual stress and improve joint toughness.

The following problems may occur in the use of 13MnNiMoR pressure vessel steel plates:

1. Corrosion: 13MnNiMoR steel plates are prone to corrosion in harsh environments such as humid, acidic, and alkaline conditions, which affects their service life.

Solution: During use, attention should be paid to anti-corrosion treatment of the steel plates to avoid contact with corrosive media.

2. Fatigue: Under the action of long-term alternating loads, 13MnNiMoR steel plates are likely to develop fatigue cracks, which affect their strength and stability.

Solution: During use, overloading and excessive vibration should be avoided, and timely inspection should be conducted on the surface of the steel plates for cracks, deformation, etc.

3. Welding issues: 13MnNiMoR steel plates have poor weldability, and problems such as welding cracks and hydrogen-induced delayed cracking are prone to occur.

Solution: During the welding process, it is necessary to control the welding temperature and speed, avoid excessive heating and cooling, and perform preheating and post-heat treatment at the same time.

4. Hot working problems: 13MnNiMoR steel plates have poor hot working performance, and issues like deformation and cracks are likely to arise.

Solution: During hot working, the heating temperature and speed should be controlled to avoid excessive heating and cooling, and appropriate cooling and adjustment should be carried out simultaneously.

Yuxin Steel provides high-quality steel products that comply with EN, ASTM, ASME, JIS, GB, and other standards. The main product categories include: boiler and pressure vessel steel plates, high-strength low-alloy steel plates, weather-resistant steel, wind tower steel, and more..

Customer Cooperation

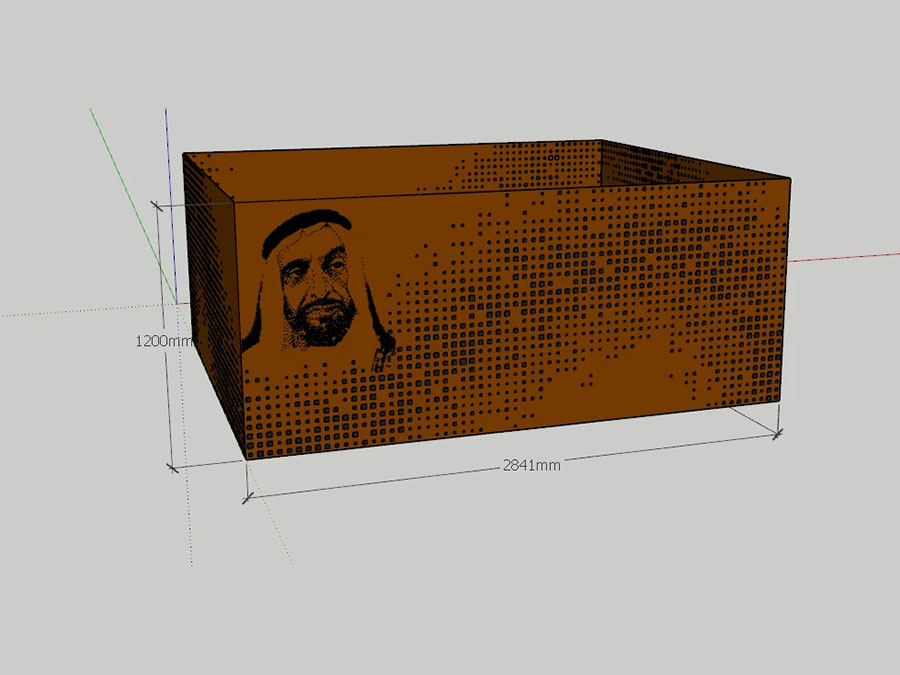

Customers choose to engage in long-term cooperation with Yuxin Steel not only because of our high-quality products and services, as well as our strong reputation in the international market, but also due to our experienced one-stop raw material supply and further steel processing capabilities!

Do you also have steel processing (machining) needs?

Yuxin Steel provides customized steel processing services based on drawings, samples, designs, and various special requirements, offering one-stop solutions for steel procurement and processing needs.Contact Info

Get In Touch

Yuxin (Tianjin) International Trade Co., Ltd.

Email :

info@chinasteelcompany.comPhone Number :

+86 15937221771Whatsapp :

+8615837212056Wechat :

+86 15937221771Inquiry

If you have any questions, please leave your contact information and we will reply to you as soon as possible.